A Case-Based Approach for the Selection of Industrial Robots in Manufacturing Sectors

Sasmita Nayak*a, Neeraj Kumar b, B. B. Choudhury c

*aPh.D Scholar, Suresh Gyan Vihar University (SGVU), Jaipur, Rajasthan, India, Email: sasmitacet@rediffmail.com

b Department of Mechanical Engineering, Suresh Gyan Vihar University (SGVU), Jaipur, Rajasthan, India,

Email: neeraj.kumar@mygyanvihar.com

c Department of Mechanical Engineering, Indira Gandhi Institute of Technology (IGIT), Odisha, India, Email: bbcigit@gmail.com

Abstract

A speedy increase in industrial robots and its usage by different manufacturing industries in a lot many diverse applications is a serious task for the selection of robots. As a consequence, the selection process of the robot becomes incredibly complex for the potential users because they have a large set of attributes and parameters of the robots are available at their disposal. It is a truth that sensible options are higher acquired when theoretical modeling of the hassle is strengthened via experience. The longer the experience, the higher the result we get. The existing work objectives at growing an approach for the choice of robots for industrial functions the place the expertise about the structure, the situation, historical instances of comparable natural surroundings are viewed aside from the robot’s facts and undertaking necessity.

Keywords: Industrial robot, Robot attribute, Robot selection

- Introduction

To mark the industrial robot implementation method effective, robot selection essential to approximate successfully and in a systematic process. The performance of a robotic utilization system is the best technique that affects not only the robot, but also the tasks, the complete structure, and the situation. Application of industrial robots is motivated by various technical and economic reasons for increasing the quality of finished products, thin out the waste, raise the level of uniformity of quality, increase the degree of operating safety, etc. The mastery of a robot is very complex in varying operational conditions like the manufacturing environment. In new trend research work robots is the main device in a variety of advanced engineering facilities. The manufacturers developed new kind robots. So, it is a difficult task for the industry to find out a suitable robot from the huse specifications of robots. Various considerations such as availability, production systems, and economics need to be considered. Moreover, many of the attributes are different and contain different units. However, none of these explanations may take care of all the loads and limitations of exact applications.

- Literature review

The implementation of industrial robots is typically recognized via making use of many parameters that are necessary and additionally that are realistic parameters[1]. i.e repeatability, precision, load size, and speed. Repeatability, precision, load size, and speed. Production company requirements aimed at evaluating these parameters are now thoroughly recognized on behalf of evaluated new techniques for examining robotic implementation growth[2]. A big quantity of attributes is used for leveling and the decision of industrial robots with the assist of TOPSIS and graphical techniques[3] which evaluating the leveling assumed via these techniques. Still, the loads given by way of the authors to the parameters had been now not steady. Khouja and kumar[4] proposed the options theory and funding assessment system aimed at the preference of robots. A funding comparison for the use of information envelopment evaluation for robotic decision is carried out[5]. A selection aid machine[6] primarily built on analytical algorithms to choose operating facilities of best in the market environment.

- Proposed Methodology for the selection of an industrial robot.

Similarity opinion is a more important component of the “experts” perception which requires for well informed regain. According to parliamentary law which embraces a concept of similarity, the given below presumptions is realized:

- The excessive resemblance among the query issue and the confirmed case stands due to excessive possible for answering the difficulty.

- Resemblance funds on a previous experience with records, which offers a quantitative value.

- A similar question has resembled

- The regain event is helpful if it is a resemblance to a query issue

According to this written report, frequent strategies usage of computable resemblance cost for the regain of valuable activities are realized using spontaneous select a parameter and searching at its matching/resemblance listing regarding the undertaking of its environment.

An established case (Case = Problem + Solution) units of facts existence, which shops the preceding ride of robotic choice. The usual facts existence includes the robotic description and methods of organizing a possible plan for the robotic determination of graph and distance designing. All steps are explained below,

•Pick-up subsequent and observe the equal process

• Extend the equal operation by accessible rebates

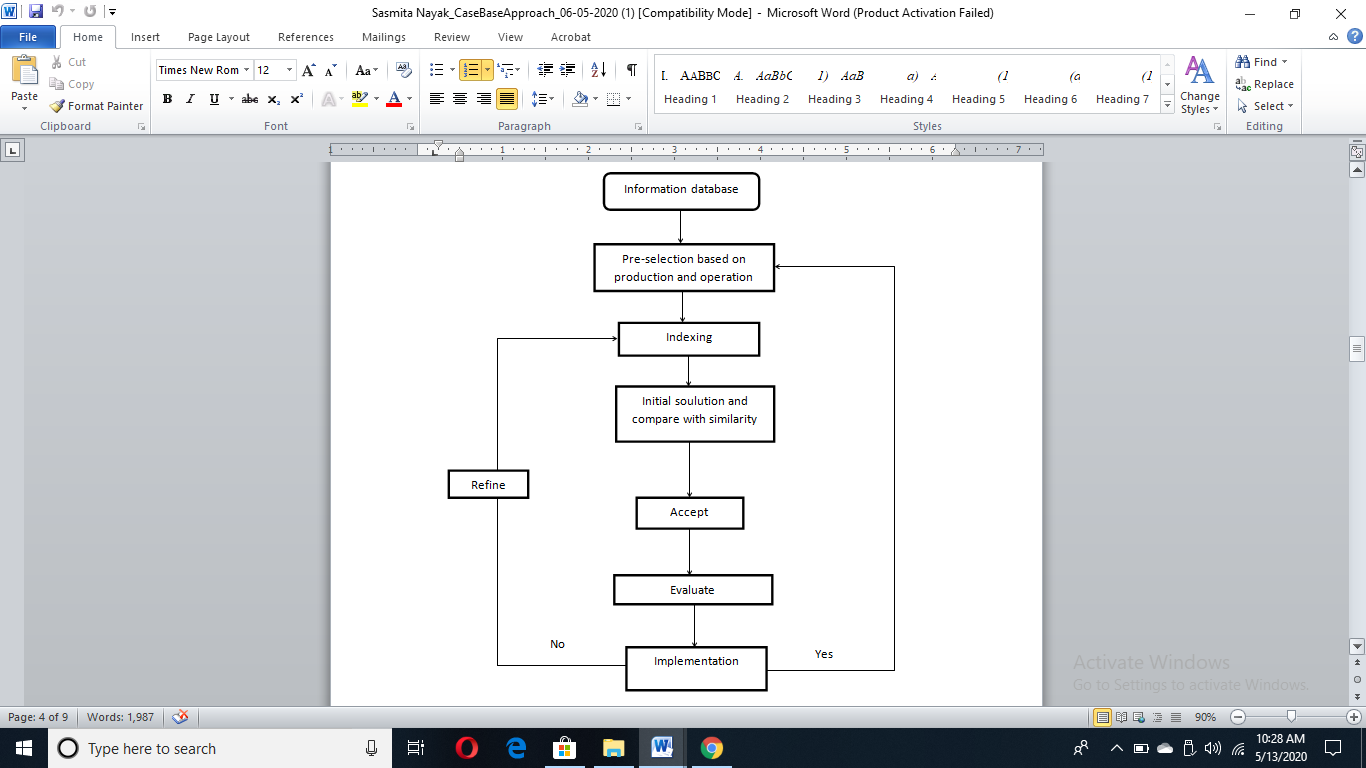

- Proposed workflow for selection of robot rank

The proposed robot selection procedure follows the main five more important tasks which are given below:

- Information database – start ruling new approach, technique execution, technique demands, and justification.

- Indexing – understand attributes, take a look at the assist of similarity case.

- Initial answer – select nearly all comparable and potential robotic use cases.

- Iteration –regulate options to appropriatethe ongoing robotic decision query.

- Implementation- follow work cell design, price estimate, plan analysis.

The continual-base similarity calculation with the attributes alike value differentiation, price, etc. is proven in Figure 1.

Figure 1. Robot selection process architecture

Table 1. parameter values of different robots

| Specification | Robot-1 | Robot-2 | Robot-3 | Robot-4 |

| (Puma (560-c) | (Adept one XL) | Fanuc Arcmate

Sr.R.J |

Staubli RX

130B |

|

| DOF | 6 | 3 | 6 | 6 |

| Pay Load | 4 kg | 3.5 kg | 8 kg | 10 kg |

| Swept Area | 320° | 260° | 270° | 300° |

| Max. Reach | 878 mm | 500 mm | 1430 mm | 1060 mm |

| Max Speed | 1.0 m/sec | 0.9 m/sec | 3.65 m/sec | 3.12m /sec |

| Price | $36,000 | $19,000 | $55,400 | $61,000 |

| Repeatability | 0.1 mm | 0.020 mm | 0.11 mm | 0.03 mm |

A few similarity dimension techniques are regarded then they have to be served not likely for the similarity calculation. The present-day function in the course of the refinement of a determination approach is defined through the record’s attributes acknowledged spot. The final problem, as its future may additionally seem to be in the case of memory, is a complete set of illuminating characteristics. The gathered records attribute results from the actual implementation case study. The geometry price of distinct instances of the robotic is given in Table 1. Table2. Register question trouble and validated the case for palletizing robotic selection. Unlikely attributes have distinct significance (loads). The following weights are viewed for the similarity calculation:

- Really very important= 13 (Ex. Manipulator reach);

- Very important = 9 (Ex: price range);

- More important = 5 (Ex: Repeatability,Payload, etc); and

- Important = 4 (Ex: Swept area)

- Somewhat important=2(Ex: Maximum end effector speed)

- Less important = 1 (Ex: Degree of freedom)

For uncomplicated reference, all useful notations for our model are summarized in Table 3.

| Sl. No. | Operation features | Information | Weight |

| 1 | Price range | $ 19500 | 9 |

| 2 | Pick up range | 55deg/sec | 4 |

| 3 | Manipulator Reach | 800mm | 13 |

| 4 | load | 5kg | 5 |

| 5 | Velocity | 1.1m/sec | 2 |

| 6 | Repeatability | ±0.2mm | 5 |

| 7 | Degree of freedom | 2 | 1 |

| 8 | Types of actuators | 0 | |

| 9 | Programming method | 0 | |

| 10 | Downtime | 0 | |

| 11 | Reliability | 0 |

Table 2. A basic case (Query problem)

Table 3. Notation for case

| Notations | Definition |

| C’ | Confirmed instance |

| i | Number of cases |

| Q | Query instance |

| I | Factor index set, I = {1, 2, …, n} |

| n | Factors figure to be nominated |

| S’ | Similarity instance |

| J | Cause table set,J={ 1,2,…,n} |

| M | load |

Table 4. Similarity computation example -1

| Features | Query Case | Similarity | Confirmed Case 1 |

| cost | $19,000 | 0.528 | $36000 |

| Swept area | 260° | 0.812 | 320° |

| Repeatability | 0.020mm | 0.2 | 0.1 mm |

| Max. Reach | 500 mm | 0.569 | 878 mm |

| Payload | 3.5 kg | 0.875 | 4 kg |

| Max Speed | 0.9 m/sec | 0.9 | 1.0 m/sec |

| Degrees of freedom | 3 | 0.5 | 6 |

Similarity of singular features

Similarity query case=

Similarity (Case 1) = 1/39 [9 ´ 0.528 + 4´0.812 + 1 ´0.2 + 13´0.569 + 5´ 0.875 +2 ´0.9+ 1 ´ 0.5] = 22.272/39 = 0.571

Similarity (Case 2) = 1/39 [9 ´ 0.974 + 4´0.962 + 1 ´0.8 + 13´0.625 + 5´ 0.291 +2 ´0.75+ 1 ´ 0.75] = 25.244/39 = 0.647

Similarity (Case 3) = 1/39 [9 ´ 0.343 + 4´0.866 + 1 ´0.181 + 13´0.327 + 5´ 0.35 +2 ´0.25+ 1 ´ 0.5] = 13.733/39 = 0.352

Similarity (Case 4) = 1/39 [9 ´ 0.311 + 4´0.812 + 1 ´0.666 + 13´0.4 + 5´ 0.291 +2 ´0.291+ 1 ´ 0.5]= 14.45/39 = 0.370

- RESULTS AND CONCLUSION

The robots are ranked by the liking primarily based on the precise points chosen to hold the purposive use in view. Granting to the outcomes of the instance problem, Fanuc Arcmate Sr.R.J that has the easiest utilization fee ought to be mentioned as the pleasant robotic substitute. The 1st ranked robotic has the most cost of DOF, price, load, and swept region the first-rate repeatability data amongst all the golems. The 2nd ranked robot has the best cost, however the lowest swept area, max. Reach and repeatability with the very best payload capability in comparison to 1st ranked robot. In parliamentary regulation to separate between these two robotic alternatives, the utilization ranking has to be regarded. A robotic choice with extraordinarily excessive utilization is greater workable to exhibit higher performance. In the facts set, P, G, and VG denote poor, good, and very accurate respectively (Table 5).

Table 5.selection of the robot.

| Sl.no. | Robots | Similarity (Relative closeness) | Ranking | Rating |

| 1 | Robot-1 | 0.571 | 3 | Very good |

| 2 | Robot-2 | 0.647 | 4 | Poor |

| 3 | Robot-3 | 0.352 | 1 | Very good |

| 4 | Robot-4 | 0.370 | 2 | Good |

Figure 2. Utilization of Robots

In parliamentary law to specify that the closeness factor plays an important role in finding the ranks of robots. the order of predilection of the robot alternatives about the closeness or similarity increase in amount principle, a ranking process turn into important. The proper utilization of Robots is presented in Figure 2. The advised technique is general for finding out an effective and efficient robot selection methodology.

- CONCLUSION

The case-based approach for the selection of an industrial robot is studied and the result analysis is successfully performed. It is found that the similarity case-based method gives a good resolution with very little error. The composition gives a methodology for the intention of simplification, between two cases based on the weighted aggregate of local similarity of all the robot features suggest computing the global similarity which helps in the choice of a suitable robot from among a large number of available alternatives robots.

Nevertheless, earlier than a conclusion is assumed, the factors such as financial reflections, accessibility, administration limitations, and global market policies, etc. may also be viewed. In the modern job, 15aspects of the robots are diagnosed and the weight has been given to most of the robotic attributes, which will restore the robotic precisely and correctly. The weight aspect coding scheme is explained with examples. The approach established through this employment would assist manufacturing engineers to pick robots for computerized work cell plan. Hence, the similarity case-based technique offers higher decision with much less time-consuming technique than different easiest method.

Reference

[1] A. Seidmann, A. Arbel, and R.Shapira, A two-phase analytic approach to robotic system design, Robotics and Computer-Integrated Manufacturing, 12, pp.181-190, 1984.

[2] O. F. Offodile, and K. PO.Ugwu, Evaluating the effect of speed and payload on robot repeatability, International Journal of Robotics and Computer Integrated Manufacturing, 8, pp.27-33, 1991.

[3] P.P.Bhangale, V.P.Agrawal, and S.K.Saha, Attribute based specification, comparison and selection of a robot, Mechanism & Machine Theory 39, pp.1345-1366, 2004.

[4] M.J.Khouja and R.L.Kumar, An options view of robot performance parameters in a dynamic environment, International Journal of Production Research, 37, pp.1243-1257, 1999.

[5] M.Bragilia and A. Petroni, Evaluating and selecting investments in industrial robots, International Journal of Production Research, 37, pp. 4157-4178,1999.

[6] A.M.Layek and L.J.Resare, Algorithm based decision support system for the concerted selection of equipment in machining/assembly cells, International Journal of Production Research, 38, pp.323–339, 2000.

Sasmita Nayak_CaseBaseApproach_06-05-2020